Equipment Identification Design Information

Identification

In order to track equipment lifecycle information, each piece of equipment to be

tracked must be permanently identified. Although this is a simple concept, there

seems to be a lot of confusion about equipment identification, instead of location

identification. The use of a stamped brass or steel tag riveted to the machine is

the preferred identification technique. Typically, these tags are readily available

and inexpensive. Complex ID strategies are discouraged, a 6-10 character alpha-numeric

ID is sufficient (Figure1). Sometimes a plant attempts to use equipment serial numbers

to identify equipment. Often a plant will find that serial numbers are not unique

and that identical equipment ordered at the same time may have the same serial number.

Also, serial numbers are complex with over 20 characters. A common problem in reading

serial numbers from a stamped nameplate is that S, Z, and 5 tend to look the same.

Figure 1

Figure 1

Design Information

Tango™ has predefined equipment design templates for hundreds of equipment types.

Figure 2 shows typical motor equipment types. These design templates have been developed

in cooperation with our users and may be modified or expanded to meet a user’s specific

need. Equipment design information is divided into required and non-required fields.

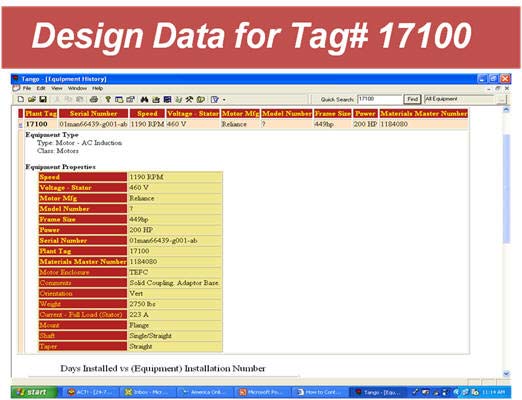

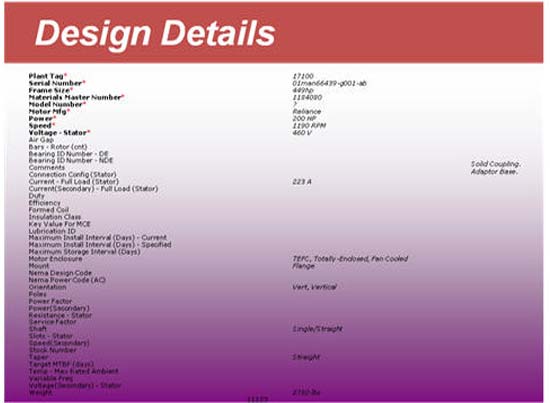

The required fields are typically the equipment ID (plant tag), nameplate information

and company stock number (figure 3,4, 5). Non-required fields define the equipment

data needed to assist in condition problem diagnosis, (like bearing IDS and number

of rotor bars or station slots), mechanical details, and sometimes installed accessories.

Figure 2

Figure 2

Figure 3

Figure 3

Figure 4

Figure 4

Figure 5

Figure 5

Search Functions

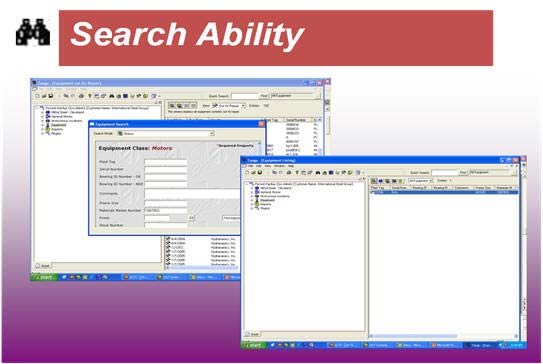

Searching for replacement equipment in spares with Tango™ is accomplished by selecting

an equipment type, then entering search criteria taken from the required fields

for the selected equipment type.

Figure 6

Figure 6

Design Documents

Associated with the design details of equipment, Tango™ allows the linking of design

documents. This may be as simple as a photo of the machine or items like manuals,

repair procedures lubrication specifications.

Figure 7

Figure 7