Reliability Engineers

Reliability Engineers, equipment engineers, area engineers, process engineers and

other plant engineer titles are responsible for solving complex problems that are

beyond the scope of plant operators, mechanics or electrician. Tangoâ„¢ provides equipment

lifecycle and root cause failure analysis tools to assist these engineers in identifying,

trouble shooting and solving expensive and complex reliability problems.

The Reliability Engineer

The reliability engineer is the single point of authority and responsibility for

assuring the reliability and maintenance action for assigned components or areas.

The reliability engineer must be one of the most knowledgeable people in the plant

for his assigned responsibility, usually with many years of experience in the installation,

repair, and operation of the assigned component. Because the reliability engineer’s

position requires a strong ability to coordinate action within the plant and with

the repair facilities, it is critical that the reliability engineer have strong

"people skills" as well as the technical skills.

From the viewpoint of an outside observer watching the reliability engineer in action,

the amount of authority and responsibility given to this position is very striking.

The reliability engineer must act as reliability coordinator, purchasing agent,

repair coordinator, and liaison between maintenance, production, PdM, and engineering.

Typical reliability engineering tasks include:

- Repair and spares coordination by working with repair facilities. Assure that the plant has the correct component replacements such that any impact of a component replacement causes minimum production loss.

- Reliability Improvement by evaluation of root cause issues and improving countermeasures if found inadequate. Maintenance protocols determined by lowest life cycle cost.

- Coordination of predictive maintenance action by reviewing PdM data and assuring that countermeasure actions are appropriate and on track. Make sure condition information is available to the entire plant and action is underway such that the impact on production is minimized.

- Inspect and review preventative and scheduled maintenance work. Inspect critical components during the operation.

The responsibilities of the reliability engineer include:

- Primary contact and relationship with the repair facilities.

- Specification of new or replacement components.

- Managing the component spares inventory.

- Supervising the routine maintenance and testing programs.

- Reviewing all failures, seeks root cause of failures, and specifies repairs, modifications, or replacements that eliminate or minimize the root cause of failure.

- Specifying and purchasing (possibly works very closely with purchasing)with the goal of lowest lifecycle cost.

- Maintaining a close working relationship with PdM staff and techs.

- Visits repair facilities regularly, and know capabilities and latest repair techniques.

- Visits manufacturers regularly and knows their capabilities and practices. Gives feedback on suspect practices and procedures.

Using all available reliability and asset information, the reliability engineer

must balance the equipment out for repair, the spares inventory, and all new equipment

purchases to assure minimum impact on plant production, enhanced reliability, and

the lowest life cycle cost. To accomplish this, the reliability engineer must know

what component models and what spare parts will be required by the plant over the

next few months; he then must make sure the appropriate units are on hand with the

proper tools, parts, and procedures for a routinely managed replacement. The tools

used by the reliability engineer to accomplish this Herculean effort are predictive

condition, historical location failure patterns, and an optimized spares inventory.

A good working relationship with component manufacturers and repair shops is required

to ensure the highest quality of reworked and new components are available and delivered

on time.

When a component begins showing signs of condition degradation, the reliability

engineer must go to work well ahead of the failure. He must explore the following

questions:

1. Does a pattern of failure in this component or location indicate an underlying

root cause of failure?

If the answer to this question is "yes", the reliability engineer must seek

a new solution to replace the component with a new or overhauled unit that is modified

to defeat the suspected root cause.

2. Should overhaul or replacement be selected for this component?

How many times has the unit been overhauled? What have previous life cycles been

like? Is the amortized cost of a new component with a longer life and higher purchase

cost better than an overhaul with it’s lower cost but shorter life? These decisions

must be made on a case-by-case basis using hard historical evidence of new and overhaul

cost and new and overhaul life cycles, and component history.

3. Does a spare exist on-site?

If the answer is yes, it must be checked to assure it is ready for service. If the

answer is no, then the spares inventory of other company facilities, used component

vendors, and new component vendors must be searched to find a suitable replacement.

The reliability engineer must assure that an inventory of critical spares is available

and optimal, such as the same general specification of 1800 RPM, 200 HP, 440v, and

445T frame components will meet the needs of the plant.

4. Are there any installation or maintenance issues to address at replacement

to make the component easier to install/remove or maintain over its life?

Items such as access, hostile conditions, and poor design may make the installation,

removal, or maintenance task very difficult. In these situations, a review of ways

to change or minimize the situation should be conducted.

Identifying Root Cause of Failure from Historical Analysis of Machine Failures

There is extensive information existing in many plants that, if analyzed for repetitive

patterns, would yield significant insight into machines or applications with a chronic

history of poor reliability.

Tracking failure data for a component in the plant along with the manufacturer and

overhaul shop, the overhaul details and the location where the component was operating

will yield a wealth of reliability information when sorted and analyzed. The reliability

of components can be studied by manufacturers to determine which brand component

is most reliable by size or application. It can be determined which rebuild shop

should do which rebuilds. One can also find out where redesign of the component

or application is necessary to improve the reliability. Sometimes replacement is

better than repair and vice versa.

Machine and location history must be maintained such that the history can be searched

and sorted to reveal basic failure patterns such as:

1. Failures by location

Often a plant has multiple identical equipment trains. It is important to understand

if there is a common primary failure mode across these locations and seek to eliminate

the root cause of failure if the life cycle of a component is less than acceptable.

2. Failures under warranty

Often plants do not process equipment warranty claims because they do not have readily

available information on purchase and installation dates.

3. Failures with less than one year of service

There exists a significant number of unreliable machines or locations within the

plant that must be identified and aggressively analyzed for root cause of failure.

4. Failures by manufacturer

Some manufacturers build a better machine for an application than others. An analysis

of the installed machines by manufacturer can focus your replacement towards higher

reliability manufacturers.

5. In service life

Sometimes a specific asset has a reliability problem which needs to be identified

and eliminated. Analysis of the in-service life by asset ID can identify these weak

components. Another value of in-service life analysis is to examine the life available

from each overhaul cycle turn. It is often said that a motor should not be overhauled

more than four times. By viewing the in-service life of the motor for each overhaul,

a decision on additional overhaul or scrapping the motor can be made.

It is possible, in many cases, to go back into paper records (purchase orders, machine

logs, maintenance logs) to put together the historical facts needed to support the

correct replacement/repair action today. The history gathered will assist in root

cause of failure analysis, and the redesign and/or purchase and/or maintenance specifications

that result from this will produce the greatest payback from the program.

Integrating Condition-Based Maintenance into the Plant Maintenance Organization

Condition-based maintenance, or predictive maintenance, is a very technical science

with data acquisition devices, databases, and analysis graphs and charts; all oriented

at predicting one aspect of a machine’s condition. This technology has proven to

be very valuable in identifying failing machines and allowing replacement before

catastrophic failure. Where most predictive maintenance programs fall short is in

integrating the predictive technologies into one concise condition view of the machine

and providing integrated recommendations for machine maintenance to the entire plant,

and tying the maintenance action back to the original PdM calls.

Integrating predictive recommendations from multiple technologies.

In many plants, predictive maintenance has not been well integrated into the overall

plant maintenance organization. Strategic Component Management utilizes the reliability

engineer to provide the link between the technical data oriented results of PdM

and the action based recommendations that are needed by plant maintenance and operations

people.

Strategic Component Management requires that the results of the predictive technologies

be integrated and an executive recommendation be issued in clear maintenance language

regarding the machine’s problem severity, expected availability, and corrected action.

The reliability engineer should be the person responsible for issuing the component’s

recommended repair action.

Integrating predictive recommendations from multiple technologies

Let’s say that each technology analyst is making great recommendations for action

based on their area of expertise. This is still not adequate for good maintenance

decisions. Plant maintenance and operations people cannot easily work with data,

actions and recommendations issued by each independent technology. Rather, they

need a single integrated recommendation that provides information about the machine

and it’s condition in a clear, concise manner.

Converting PdM technology data into action-based recommendations is not an exact

science. The common question "When will it fail" cannot be accurately answered because

of the many unknown aspects of machine failures. Strategic Component Management

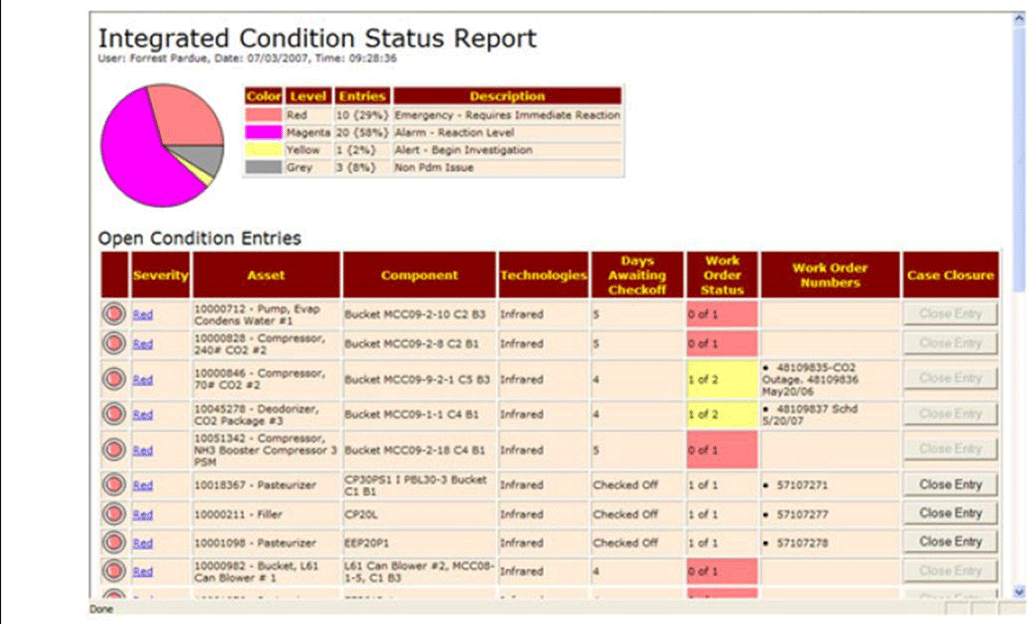

utilizes the color code severity index where the action based on severity is clear.

These are:

Red - Machine is not reliable and could fail at any time.

Yellow - Machine is definitely degraded, but should reliably operate

for over a month longer.

Blue - An early stage fault is suspected. Corrective action may

be taken to extend the machine’s life. The machine should reliably operate for over

three months.

Green - The machine is fully reliable and shows no sign of degradation.

Integrated Condition Status Report

Integrated Condition Status Report

Benefits & Payback

The payback from reliability engineering can be very significant. Typically, payback

is obtained from:

1. Reduced machinery life cycle cost

The most significant cost savings from this technology is the lowering of a machine’s

life cycle cost by increasing it’s usable life between replacements or overhauls.

Many poor reliability machines can be increased in life several-fold with the application

of root cause failure analysis and precision corrective maintenance technologies.

2. Lower repair/replacement cost

The reduction in overhaul and replacement cost is accomplished through building

a partnership with the overhaul or component manufacturers; which allows volume

cost reductions and the imposition of stringent quality requirements. The standardization

of spares to allow more widespread use of a single class of motor provides significant

savings.

One large facility reported a 40% reduction on repair and replacement cost when

comparing their annual cost from before implementing strategic component management

and three years after the implementation of the program.

3. Increased production from higher availability

Increasing machinery reliability has a direct effect on increasing production. Having

more reliable machines means less maintenance downtime and more production availability.

One plant, after having implemented Strategic Component Management for several years

notes an increase of up to 8 hours a week of increased production.

4. Providing integrated recommendations to the plant

In many manufacturing facilities, predictive condition monitoring is performed on

thousands of machine components. Typically an exception report of machines ranked

by severity is issued by each technology. Usually this report is issued on hard

copy or in e-mail and followed up with a phone call for the most critical and severe

cases.

Typically in most plants the maintenance responsibility is broken down into areas

or component types. Area maintenance only wants to see the condition of "their"

machines. Strategic Component Management recommends that an integrated condition

report be available broadly over the plant computer network, and allow each maintenance

person to only view the machines they are interested in or responsible for. Figure

1. shows an example integrated condition report.

5. Completing the loop - tying maintenance action back to the PdM call.

It is typical in most plants that the predictive maintenance technologists do not

get very good feedback on repairs and findings from the maintenance repair organization.

PdM needs this information to:

- Close out the fault case.

- Verify the quality of predictive calls.

- Trigger the collection of certification measurements to assure a good repair.

- Establish a new machine baseline.

6. Component Replacement & In-Place Spares

Major component replacement and in-place repairs are led by the reliability engineer.

This reduces the stress and workload of area maintenance management, planning, and

parts expeditors. This ensures a top quality job completed on-schedule.