Maintenance Work Planners

Tango Web Service, in a supplemental role to the plant's CMMS system, can streamline

the flow of equipment condition status between analysts, reliability engineers,

and maintenance planners.

A couple of years ago, one maintenance planner at an automobile assembly plant in

the Southeast would spend several hours each Tuesday reviewing e-mail reports coming

from condition monitoring contractors providing vibration, oil, IR thermography,

and ultrasonic analysis. After wading through the different formats and severity

scales for each technology report, he would make decisions about which assets needed

work orders in their SAP system.

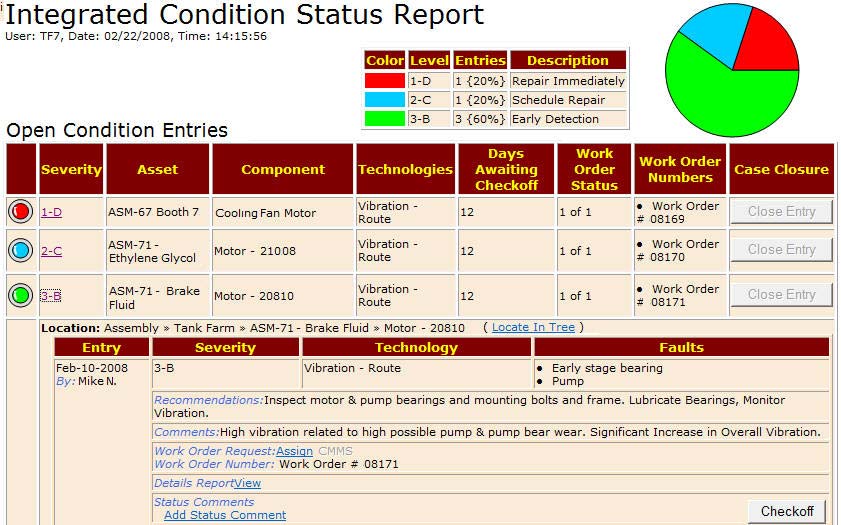

As soon as the PdM analyst enters information about a high severity problem, Tango™

notifies the maintenance planner by e-mail and he uses his web browser to open the

Integrated Condition Status Report (ICSR) for details (Fig 1). The components with

the highest severity problems are at the top of the list, and he can quickly see

if other technologies have also reported a problem with that asset. He can drill

down into findings and recommendation details, plus open any supporting documents

such as vibration spectra or thermography images.

Fig 1: Web report highlights assets with condition problems,along with the analyst's detailed findings, recommendations, and work order status.

Fig 1: Web report highlights assets with condition problems,along with the analyst's detailed findings, recommendations, and work order status.

The maintenance planner says he appreciates the timeliness of the e-mail notification,

and the convenient web access for checking out the reported problem. Now, instead

of waiting for his Tuesday review, he's able to generate the SAP work orders throughout

the week as they come up. "I always include the ICSR information in the work order",

as well as a copy of the linked IR thermography image, to help out the assigned

work team.

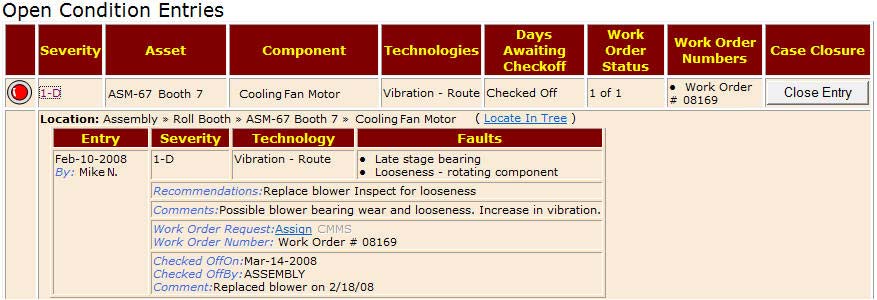

Now this maintenance planner doesn't have to wade through different technology reports

each week to decide what work orders to generate, so he uses his Tuesday review

to look at the status of open condition-based work orders and check off those that

have been completed. He includes comments taken from the work order summary (Fig

2).

Fig 2: Monitoring analysts appreciate feedback letting them know what happened with a condition call.

Fig 2: Monitoring analysts appreciate feedback letting them know what happened with a condition call.